Who is behind Flikka?

The seed of FLIKKA boards grew its first roots in year 2001 when our shaper Luka Jureš linked his passion for windsurfing with enthusiasm for handwork and knowledge gathered from composite production industry, to make his first board ever in his home garage. From that moment on, his destiny was sealed: he started off by making boards for himself and his closest friends, but soon enough the word of outstanding quality of his boards got the windsurfing community buzzing. Subsequently, with the help of his friends and family, FLIKKA boards were born.

About us

Today we are one of the leading custom builders in the world. A team of 15 people shapes, creates and ships almost 1000 boards per year, worldwide. Our team riders compete in PWA and IWT on the highest level and there are many more who enjoy windsurfing on all levels. There are a growing number of test centers where you can try them. And to our great pleasure, they can be seen in action on the best spots all over the world.

Technology

We started as every other custom builder. A lot of dreams, desires and some broken boards. But most of all we were driven by ideas on how to make boards better and stronger. We stayed persistent and learn how to make it right. Orders increased and we were looking how to respond to the demand and further increase the quality of our product.

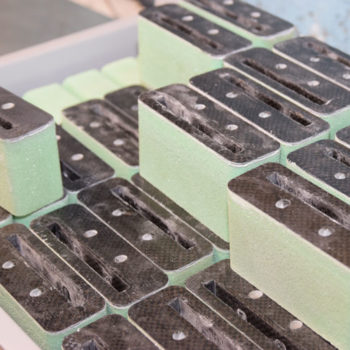

2001: From the first board that we made, we were using stainless steel strap inserts. Plastic inserts on production boards were always a weak spot – ripped out, damaged thread, punctured because of too long screw,… All this problems were solved with our in house developed inox insert system. Result? Lower weight, no rip-outs, no strap turning, no damaged threads.

In 2010 we introduced CNC shaping technology. That gave us the option to improve the transformation of shape ideas into real products, improve the product development, achieve shape consistency and increase production volumes at the same time.

In 2011 we started to produce our own G-10 fins on a second high precision CNC machine. Which is just great, because we killed two birds with one stone – constant in house production and development of fins tuned to work best on our shapes and avoiding far east products, which was always one of our goals.

In 2012 we were confident enough that industry standard plastic mast and finboxes don’t achieve needed quality and we developed them in-house. Made of carbon/dyneema they are 40% lighter and twice as strong.

2019: Someone may say there is nothing to add, but we go to great lengths to further increase the quality and lower the weight of our boards. That’s why we’re introducing custom made titanium screws for straps and fins, which are 40g lighter per/board then normal inox screws.

Near future: Our plans are to introduce and interconnect robotic technology in our current production and to further digitalize ordering and production process.

We tried every possible resin, core, airex, fiber material and overlapping techniques, stingers, paint, pads, valves,… to get where we are today. 9 available constructions, every one with clear advantage for dedicated situation.

We continue developing. Small steps or big. It doesn’t matter as long we add a little bit of performance, strength or remove weight. And once we find it, we implement it immediately. No need to wait for next Model year.

Business philosophy

We believe windsurfers deserve a choice. We created a mix of industry and hand-craft approach that allow us to transform every windsurfer’s desire into a personalized board. We put the quality and board’s performance into first place.

We prove windsurfing boards can be successfully built in the middle of Europe from local materials and suppliers. Changed customer behavior, marketing approach possibilities and direct distribution channel options dictate new approach. We follow the goal to be in direct contact with customers and offer the excellent product for an acceptable and competitive price.

We also managed to solve a problem that most custom producers have – long delivery times. Despite growing volumes, we have developed a custom production software that allow us to have a perfect overview over each order and board in production which gives us good control to stick with promised delivery times.

Produced by windsurfers for windsurfers – almost every member of Flikka crew is a passionate windsurfer, surfer or SUP-er. We strongly believe that passion is a crucial part of a good product. Even though the company is almost empty on a windy day…

We are driven by shape and material development not by yearly marketing plans. We implement improvements immediately and we don’t do artificial changes to satisfy new yearly marketing catalogue.

Sustainability

We enjoy being in nature. Like many of you, we see how the environment is under pressure from the modern world, consumption and plastic materials. We can’t create a fully bio-degradable board yet but we try to minimize the pressure we put to this beautiful planet. Unfortunately, high-end materials that we use are mostly not really eco-friendly. That’s why we developed two areas where we can make a difference:

1. We produce boards that have a longer lifespan compared to production boards. This way fewer boards are produced and at some point dumped.

2. Local raw materials: a factory that produces EPS core is 3 km away, PVC foam producer is 100 km away and epoxy resin that we use is from Europe, as well all other materials that we use. Boards sold in Europe have a shorter transportation route. This way we minimize the transport carbon footprint.

Why choose Flikka custom boards

Quality – hand made by windsurfers. There are no shortcuts on details.

Matching needs – the board shape can follow your needs. No need to compromise from a limited selection. You can influence every detail or take a proven specification.

Personalization – besides the completely personalized shape, everyone can also choose his favourite design and other board details.

Long term value – you don’t have to ba a victim of artificially created value from every year new models and falling prices at the end of each season.

Warranty – our regular construction gives you 2 years guarantee against failure of materials or workmanship (delamination, softening of the hull, inserts, fin and mast boxes), and 1 year guarantee against breakage. Hardcore construction even more.

Support – pre and post sale. In case you got any questions or doubts we are always available to help you choose the right board for you. If you will ever need a suggestion about setup or repair we always personally take care of our customers.

Delivery time – we are offering 4-6 weeks delivery time. If your life depends on it we can usually make it even quicker. We stick to the delivery time we communicate at time of ordering. Even better, our CORE line boards are usually on stock and can be shipped immediately.

Worldwide delivery – we get orders from all parts of the world and can help to get a competitive shipment solution.

Confidence – We are producing many boards (almost 1000 custom build boards a year), and we have learned to give valuable advice while choosing your next dream board.